Services

Hanseatic Crane Services offers a comprehensive range of services specifically tailored to the needs of crane operators.

Our goal is to provide our customers with high-quality solutions to maximize the efficiency and safety of crane systems. Here are our key areas of expertise:

Refurbishment

Refurbishment of crane systems offers a cost-effective alternative to purchasing new equipment. Through targeted modernization and the replacement of components with higher-performance alternatives, we extend the service life of your equipment and enhance its performance. Our experienced technicians assess the condition of your cranes on site and, in close consultation with you, develop tailored measures – which our team implements efficiently, safely, and with minimal downtime. This ensures that your material handling processes remain reliable and future-proof.

Maintenance and Repairs

Regular maintenance is essential for the safe and reliable operation of crane systems. Our specialized service team carries out maintenance and repairs in accordance with manufacturer specifications and current regulations – efficiently, on schedule, and with a clear focus on your operational safety. This helps prevent unplanned downtime, extends the service life of your equipment, and ensures that your material handling processes run smoothly.

Inspections

Professional inspections form the foundation for safe and trouble-free crane operation. Our experienced specialists systematically examine your cranes for damage and functional or safety-related deficiencies – using state-of-the-art equipment and comprehensive documentation. This allows us to identify potential issues early and provides the basis for planned maintenance measures as well as the long-term service life of your equipment.

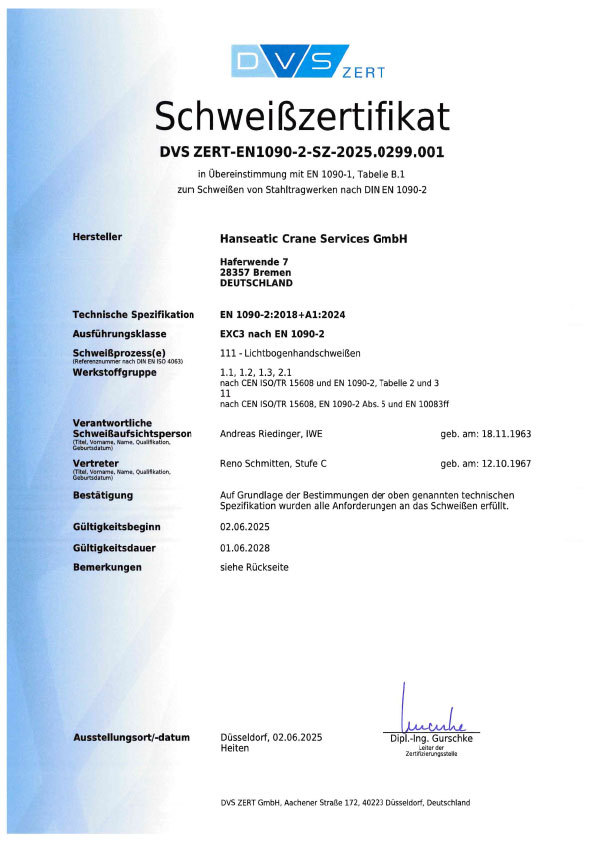

Welding on Load-Bearing Components

Our welding department is also available to assist you with all welding-related issues and the development of repair concepts.

Spare Parts

We source exactly the spare parts your crane systems require – tailored, high-quality, and delivered on time. Thanks to our reliable network of suppliers, we ensure fast and seamless procurement – both nationally and internationally. This helps you prevent unplanned downtime and guarantees the operational readiness of your equipment at all times.

DGUV Inspection

We carry out recurring inspections of crane systems in accordance with DGUV requirements – reliably, professionally, and fully documented. Our certified crane experts check all safety-relevant components and functions of your cranes to ensure operational safety and compliance with legal regulations.

Engineering Services

Our engineering services for crane systems include structural calculations, mechanical engineering analyses, and design planning. With technical expertise and many years of experience, we develop customized solutions focused on safety, efficiency, and durability. We support your project from the initial concept to technical implementation – worldwide, reliably, and with true Hanseatic professionalism.